S69B2 Mast Section For Tower Crane Masts

- ZCJJ

- China

- 10days

- 50pcs

Tataouine Tower crane, Tozeur Tower crane,

Zaghouan Tower crane,

Products Specification

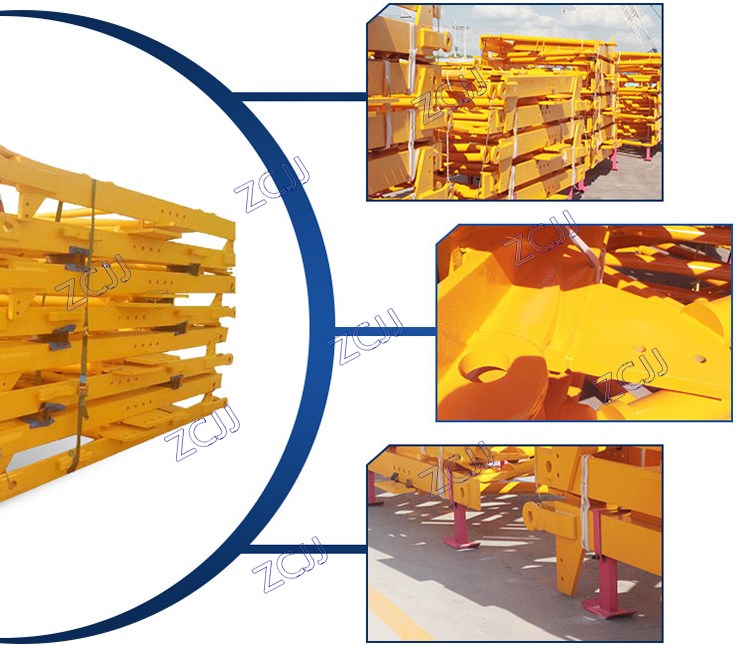

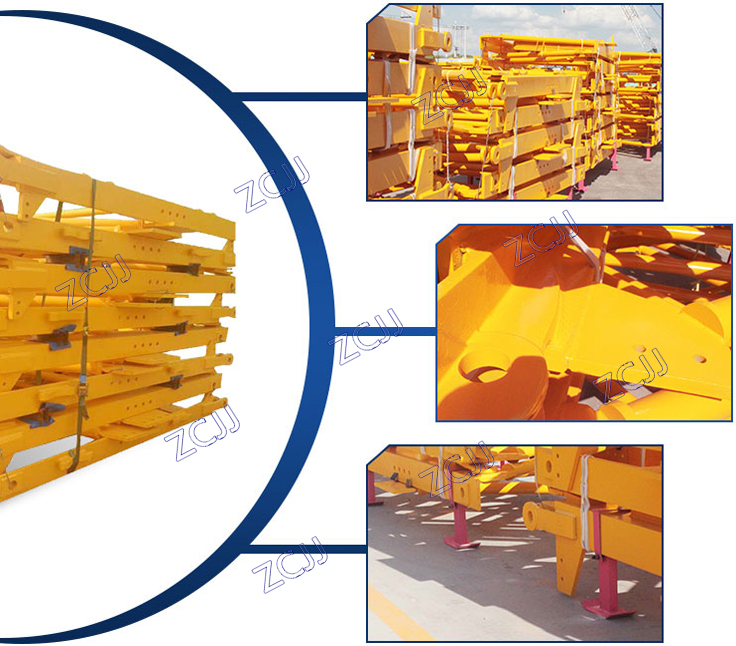

Type , Model: S69B2 Mast Section For Tower Crane Masts

Size: 2mx2mx3m

Materials: Q345B

Within: Pins, Ladder, Platform

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

S69B2 Mast Section For Tower Crane Masts

Tower Crane Knowledge sharing:

What are the basic requirements for the safety operation technology of Tower hoist?

The tower crane operator must master a solid tower crane operation technology to avoid tower crane accidents caused by improper operation. In this article the majority of tower crane practitioners discussed, tower crane work safety operation technology basic requirements

(1) Scaffolding and demolition of scaffolding can only be carried out after the construction workers have been assessed for special operations and work safety techniques at high altitudes and have obtained special operation licenses and passed medical examinations.

2, the scaffold must be strictly in accordance with the construction plan and operation rules of the special tower hanging set up, in the construction of the correct wear and use of labor protection supplies.

3, scaffolding must not be mixed with steel, bamboo, the main force rod parts, such as vertical bar, large horizontal bar, small horizontal bar and scissors support, etc., must use the same material material in the same building facade.

4, set the tower pole should be equal distance, vertical distance should not be more than 1.8 water, scaffolding should not be more than 20 cm from the wall. If it is greater than 20 cm, isolation measures must be taken.

5, the length of the main rod of the scaffold must be staggered; The joint of the steel pipe scissors must be attached, and the length of the joint must not be less than 50 cm.

6, the top of the scaffold must be capped according to the requirements of the regulations; The vertical pole should be less than 50 cm from the cornice, and the outer pole should be 1 meter from the cornice of Gaochu. On the outside of the scaffold, from the second step, 1.2 meters high protective railings and 30 meters high retaining rods must be set at each step

S69B2 Mast Section For Tower Crane Masts

The top row of handrails should not be less than 2, with heights of 1.2 meters and 1.8 meters respectively.

Steel pipes and fasteners used for erection must conform to the National standards, and the use of steel pipes with severe corrosion, bending deformation or cracks is prohibited. The fasteners for brittle cracking, deformation, and sliding wires are also prohibited.

Scaffolding must be carried out in accordance with the specifications, that is, horizontal and vertical, the connection is strong, the bottom foot is really, the layers are pulled, the support is straight, smooth and flat, and the facilities are complete and firm.

9, scaffolding inside the bar and external wall between the required protection. The ramp on the scaffolding shall have an independent support system. The rest platform at the corner shall not be less than 2 square meters, the slope of the ramp shall not be greater than l:3, and the spacing of the Anti-Slip bars shall not be greater than 30 cm.

10, the bottom of the steel pipe scaffolding pole should be vertically stable on the concrete cushion or concrete foundation, and set vertical and horizontal sweeping rod.

The rubbish and debris on the scaffolding must be cleaned up frequently. If it is found that the foot piece is broken or the rod piece is bent or deformed, it should be replaced in time.

12, strictly prohibit on the scaffolding cable wind rope and set lifting lever; Do not put the material slide on the scaffolding and set up the material receiving platform; Do not use slant pull, slant hanging from scaffold feed.

13, the scissors supporting at the ends of the frame, at the corners, and on the outside must be connected, and the structure and quantity of the tie points meet the requirements.

S69B2 Mast Section For Tower Crane Masts

14,

The distance between the scaffolding and the various transmission lines must meet the prescribed safety distance, otherwise the necessary security measures must be taken. When missing and removing the frame, you must pay attention to safety and be careful not to injure people after the rod part touches the high-voltage line.

15The safety protection, strength, stiffness and stability of the scaffolding with an operating surface of more than 2 meters must also meet the relevant requirements.

S69B2 Mast Section For Tower Crane Masts

16.Scaffolding must have a good lightning proof grounding device, and the grounding resistance is not greater than that of Looumu.

17, the removal of scaffolding and material hoist should be clearly directed by a special person.

Before the demolition, it is necessary to conduct a comprehensive inspection of the body or other pull material, the connection between the hoist and the scaffolding, and the building; Designated person alert when dismantled

Demolition must be carried out layer by layer according to the inverse order of the arrangement, and it must be done step by step. It is strictly forbidden to dismantle it at the same time.

S69B2 Mast Section For Tower Crane Masts

Remove steel pipes, footplates, fasteners, safety nets and other objects shall be transmitted downward or suspended by a rope and shall not be thrown downward.

Steel pipes, footcuts, fasteners, safety nets, etc. are classified into categories, neatly stacked, and placed with signs.

After scaffolding is set up, it must apply for acceptance.

The factory to the tower crane work safety operation technology basic requirements for the temporary summary of these, hope to the vast tower crane work to help.

The factory will continue to summarize and continue to supplement.

When the steel rope of a tower has one of the following characteristics, it is necessary to take scrap measures

The steel rope of the tower is responsible for lifting heavy objects, and the tension force of the wire rope is very large.

S69B2 Mast Section For Tower Crane Masts

Therefore, the maintenance of steel wire rope tower hanging should be careful, especially in accordance with the regulations, strict implementation of the scrap standards of steel wire rope tower hanging. Under what circumstances should the steel rope of the tower be scrapped? Tower hanging construction machinery according to the characteristics of the tower hanging steel wire rope summarized as follows, when the tower hanging steel wire rope has one of the following characteristics, it is necessary to take scrap measures.

1. Number of broken wires

If the wire rope is scrapped, then the number of wires broken by the wire rope 6 × 19-d(D wire rope diameter) exceeds 5 in the 6D length and the number of wires broken in the 30D length exceeds 10.

2. Generating deformities

Steel rope scrap will lose its normal shape and produce deformities, such as waves, cage-like distortions, rope extruding, wire extruding, rope diameter partial enlargement, twisted knot, rope diameter partial reduction, part compressed, bending.

3. Wear

Although there is no broken wire at the end of the wire rope, the wire rope wears 40 % of its diameter, or when the wire rope decreases by 7 % or more relative to the nominal diameter, or the wire rope is obviously bent.

YONGMAO STT983 Mast section

YONGMAO STT753 Mast section

YONGMAO STT553 Mast section

YONGMAO STT403 Mast section

YONGMAO STT293 Mast section

YONGMAO STT253 Mast section

YONGMAO STT200 Mast section

YONGMAO ST80/238 Mast section

YONGMAO ST80/160 Mast section

YONGMAO ST80/116 Mast section

YONGMAO ST80/75 Mast section

YONGMAO ST80/60 Mast section

YONGMAO ST80/31 Mast section

YONGMAO ST70/50 Mast section

YONGMAO ST75/32 Mast section

YONGMAO ST70/32 Mast section

YONGMAO STL720 Mast section

YONGMAO STL660 Mast section

YONGMAO STL530 Mast section

YONGMAO STL420 Mast section

YONGMAO STL420A Mast section

YONGMAO STL330 Mast section

YONGMAO STL230 Mast section

YONGMAO STL203C Mast section

YONGMAO STL180 Mast section

SYM S315K16 Mast section

SYM S315K18 Mast section

SYM S315K16B(QTZ315) Mast section

SYM K50/50(QTZ450) Mast section

SYM K50/50B(QTZ450) Mast section

SYM K50/50C(QTZ450) Mast section

SYM K50/70(QTZ500) Mast section

SYM K50/70B(QTZ500) Mast section

SYM S450L25(QTZ450) Mast section

SYM S450L25B(QTZ450) Mast section

SYM S560K25(QTZ560) Mast section

SYM S560K25B(QTZ560) Mast section

SYM S650H24(QTZ500) Mast section

SYM S650M25(QTZ650) Mast section

SYM S650M25B(QTZ650) Mast section

SYM S650M32(QTZ650) Mast section

SYM S650M32B(QTZ650) Mast section

SCM C3208 Mast section

SCM D650 Mast section

SCM D360 Mast section

SCM D320 Mast section

SCM D230 Mast section

SCM D160 Mast section

SCM D120 Mast section

SCM D120 (A) Mast section

SCM D90 Mast section

SCM D60 Mast section

SCM P2200 Mast section

SCM P1200 Mast section

SCM P900 Mast section

SCM P600 Mast section

SCM P360 Mast section

SCM P8042 Mast section

SCM P8030 Mast section

SCM P7527 Mast section